Seamless Steel Pipe Ultrasonic Testing Method

Testing principle

The ultrasonic probe can achieve energy conversion and ultrasonic sound energy between the physical characteristics of the propagation in elastic medium when the pipe is the basis of the principle of ultrasonic flaw detection. Directional transmission of ultrasonic beam propagation encountered in the tube defect, produces both the reflected wave has produced wave attenuation. After signal processing flaw detector, such as the use reflection detection, defect obtained echo signals, such as the use penetration testing method, by virtue of the degree of attenuation of the wave to get the defect signal. Both can give a quantitative defect indication by the instrument.

Using the piezoelectric effect or electromagnetic induction principle can stimulate different types of ultrasonic wave in the tube. Therefore, the piezoelectric ultrasonic and electromagnetic ultrasonic examination ultrasound can be used for pipes. But EMAT only for ferromagnetic materials.

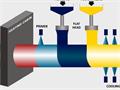

Testing methods

Longitudinal wave (or wave plate) reflection method (or penetration method) in the probe and the pipe relative movement state auto inspection, the only special large-diameter pipe is available for manual inspection. Automatic or manual inspection shall ensure that when the beam to scan the entire surface of the tube. Defect inspection longitudinal beam propagation direction in the circumferential wall; test transverse defects in the wall beam travels along the tube axis direction. Longitudinal and transverse defects inspection should be carried out in two opposite directions of the tube.

When the demand side is not presented for inspection transverse flaw inspection party only longitudinal defects. Agreed by both sides, longitudinal and transverse defects inspection can be carried out only in one direction of the tube.

Automatic or manual selection of test time should be coupled to good effect, and without prejudice to the coupling medium pipe surface.

- Anterior : Package of Steel Tube

- próximo : Pipe Geometry and Appearance Inspection