Hunan Standard Steel Co.,Ltd es uno de los miembros de Husteel Industry Group, como fabricante profesional de tuberías y accesorios de tubería de acero dulce, que tiene un sistema completo de producción ... Más

Fábrica GrupoQuality Requirements of Seamless Steel Tube Billet

fecha:2016-05-25

Vista:2668

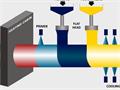

Since the rotary piercing deformation characteristics of the tube quality (especially seamless steel pipe surface quality) proposed strict technical requirements.

(1) Surface tube directly affects the quality of the outer surface of the finished steel quality. In the hot-rolled steel production, we must first carry out strict inspection tube surface state, the outer surface of the tube is allowed to have scarring, cracks, seams, grooves, folds, dimples, ears, pores, pitting, trachoma and non-metallic inclusions and other defects. When the defect depth of more than 0.7 to 1.0 mm, with tube defects can not be heated and burned, but remains on the surface of the shell will expand any defects in piercing the deformation process, so that any defects are defects in the outer surface of the pipe piercing and rolling deformation process extended so that the defect in the outer surface of the steel pipe to deepen becomes long, resulting in waste. Local defects of the above should be cleared in time, but the process defect depth must not exceed 5% of the tube diameter.

(2) Low magnification tube. Tube of internal quality in general are in the low magnification tube for the assessment basis. The low magnification of the tube should not have visible residual shrinkage ≥1 level, FanPi, delamination, bubbles, blisters, non-metallic inclusions, white spots and cracks. After the general loose, center porosity, segregation, subcutaneous bubbles and other defects by standard sample rating shall not exceed the following requirements: the production of general-purpose ordinary carbon steel pipe tube general loose ≤4 grade level segregation center porosity ≤3 ≤3 grade ≤2 mm deep subcutaneous bubbles produces high-pressure boiler tubes, alloy pipe tube general loose loose ≤2 ≤2 grade level center segregation level ≤2 depth subcutaneous bubbles are not allowed.

(3) Tube microstructure. Alloy and high-alloy steel pipe production with the special requirements of the tube, in addition to inspecting the low times outside the organization, but also for the microstructure (ie metallurgical high-powered organization) test to determine the non-metallic inclusions (such as sulfide, oxide and carbides) the content and form of distribution, identification band structure and decarburization layer.

(1) Surface tube directly affects the quality of the outer surface of the finished steel quality. In the hot-rolled steel production, we must first carry out strict inspection tube surface state, the outer surface of the tube is allowed to have scarring, cracks, seams, grooves, folds, dimples, ears, pores, pitting, trachoma and non-metallic inclusions and other defects. When the defect depth of more than 0.7 to 1.0 mm, with tube defects can not be heated and burned, but remains on the surface of the shell will expand any defects in piercing the deformation process, so that any defects are defects in the outer surface of the pipe piercing and rolling deformation process extended so that the defect in the outer surface of the steel pipe to deepen becomes long, resulting in waste. Local defects of the above should be cleared in time, but the process defect depth must not exceed 5% of the tube diameter.

(2) Low magnification tube. Tube of internal quality in general are in the low magnification tube for the assessment basis. The low magnification of the tube should not have visible residual shrinkage ≥1 level, FanPi, delamination, bubbles, blisters, non-metallic inclusions, white spots and cracks. After the general loose, center porosity, segregation, subcutaneous bubbles and other defects by standard sample rating shall not exceed the following requirements: the production of general-purpose ordinary carbon steel pipe tube general loose ≤4 grade level segregation center porosity ≤3 ≤3 grade ≤2 mm deep subcutaneous bubbles produces high-pressure boiler tubes, alloy pipe tube general loose loose ≤2 ≤2 grade level center segregation level ≤2 depth subcutaneous bubbles are not allowed.

(3) Tube microstructure. Alloy and high-alloy steel pipe production with the special requirements of the tube, in addition to inspecting the low times outside the organization, but also for the microstructure (ie metallurgical high-powered organization) test to determine the non-metallic inclusions (such as sulfide, oxide and carbides) the content and form of distribution, identification band structure and decarburization layer.

- Anterior : Diameter and Tolerance of Seamless Steel Pipe

- próximo : Thread Seal of Tubing & Casing