Hunan Standard Steel Co.,Ltd es uno de los miembros de Husteel Industry Group, como fabricante profesional de tuberías y accesorios de tubería de acero dulce, que tiene un sistema completo de producción ... Más

Fábrica GrupoHow to heat the cold drawn steel pipe

fecha:2017-05-19

Vista:2335

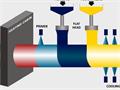

Cold drawn steel pipe in the production and processing of the technical requirements are particularly high, cold drawn steel pipe under the action of heat, because the surface of the temperature is relatively high, faster shrinkage, the speed of condensation is relatively fast, in the The process of condensation is more susceptible to stimulation! In order to pursue the high quality of the physical and chemical properties must be cold-drawn steel pipe heat treatment.

The faster the cooling rate, the higher the carbon content and the composition of the alloy, the greater the uneven plastic deformation produced by the thermal stress during the cooling process, and the greater the residual stress formed. On the other hand, the steel in the heat treatment process due to changes in the organization that austenite to martensite transformation, due to the increase in specific volume will be accompanied by the expansion of the workpiece volume, the workpiece has changed the various parts, resulting in volume growth is inconsistent and produce tissue stress. The ultimate result of tissue stress changes is the tensile stress of the surface, the compressive stress of the heart, and the opposite of the thermal stress. The size of the tissue stress is related to the cooling rate, shape, chemical composition of the workpiece in the martensitic transformation zone.

Cold-drawn steel pipe heat treatment technology is related to the hardened steel pipe hard, the volume of the perfect and the relationship between this technology.

The faster the cooling rate, the higher the carbon content and the composition of the alloy, the greater the uneven plastic deformation produced by the thermal stress during the cooling process, and the greater the residual stress formed. On the other hand, the steel in the heat treatment process due to changes in the organization that austenite to martensite transformation, due to the increase in specific volume will be accompanied by the expansion of the workpiece volume, the workpiece has changed the various parts, resulting in volume growth is inconsistent and produce tissue stress. The ultimate result of tissue stress changes is the tensile stress of the surface, the compressive stress of the heart, and the opposite of the thermal stress. The size of the tissue stress is related to the cooling rate, shape, chemical composition of the workpiece in the martensitic transformation zone.

Cold-drawn steel pipe heat treatment technology is related to the hardened steel pipe hard, the volume of the perfect and the relationship between this technology.